Page updated: 15 April 2014

Introduction (including Rant and Warning!)

Introduction (including Rant and Warning!)

The Boat Safety Scheme was devised in 1997 by British Waterways and the Environment Agency, the two largest inland navigation authorities in the UK. It had a bad start. In some cases inspectors, compelled under the regulations set out in the scheme, insisted upon changes to a boat that actually increased the dangers and caused fires.

After much protest, an independent review of the Scheme in took place in 2001. Some of the bureaucratic idiocy was reduced and the regulations split into essential requirements for "Safety" and "Environmental" reasons and an advisory section for "Best Safety Practice".

Of course, the promoters claim there is much more to the scheme than the issue of a certificate. However, for many boat owners this is all that matters. The cynics case is only strengthened by the fact that although the certificate remains valid for four years most navigation authorities have no system in place to check on any work carried out between one examination and the next and that no statistics are published to demonstrate that damage, injury or even fatalities have been reduced by the scheme.

Whatever the merits of the scheme, it is important to all UK-based SeaHawk owners, even those not immediately affected by it. This is because we now have almost half the waters on which SeaHawks are sailed subject to the scheme. Therefore, any changes that affect a boat's ability to pass BSS certification might seriously affect its value.

Overview

Overview

To gain a BSS certificate a boat has to meet various requirements. You are, therefore, encouraged to download the BSS Examination checking Procedures booklet, available from the BSS Web Site.

Unfortunately, the requirements were originally specified with narrowboats and other large cruisers in mind, so it can be difficult to know how to apply some clauses to a small yacht. This page attempts to provide information on how the requirements are interpreted by BSS examiners experienced in inspecting SeaHawks.

The examiner's check lists includes the following headings:

- Permanently Installed and Fixed Engines

- Electrical Systems

- Electrical Propulsion Systems

- Outboard and Portable Combustion Engines and Portable Fuel Systems

- Fire Extinguishing and Escape

- Liquefied Petroleum Gas (LPG) Systems

- Appliances and Flues

- Pollution Prevention Systems

Permanently Installed and Fixed Engines

Permanently Installed and Fixed Engines

Reports from the owners of inboard engined SeaHawks on their experience of obtaining a BSS certificate are awaited. Please use the Forum to provide any information.

Electrical Systems

Electrical Systems

Many SeaHawks have no permanent electrical installations and so avoid any of the issues reported in this section.

"Imagination" is one boat that is affected as it is used with an electric outboard and on-board solar charging system. The engine is powered by an 85a/h leisure battery, This is charged by a SOLAREX MSX10L solar panel, sited on the foredeck. The current is fed to the battery through a SOLSUM 5.0X charge controller unit. This unit is designed to cut power to prevent battery gassing through over charging. Additionally, the unit has output terminals designed to provide power to a radio or similar small current device. It will also cut power to devices connected to this output if battery voltage drops so low that the battery might be damaged.

The solar panel has a hard-wired cable that emerges from a sealed connector unit. The cable passes through a grommet on the main deck and into the cabin. This does mean that the cable is subject to regular flexing at this point, but no objection to this was made by the BSS examiner who passed the installation.

Once in the cabin the cable passes through a series of lightweight plastic conduits that are fixed either by adhesive or resin to the underside of the foredeck and gunwales.

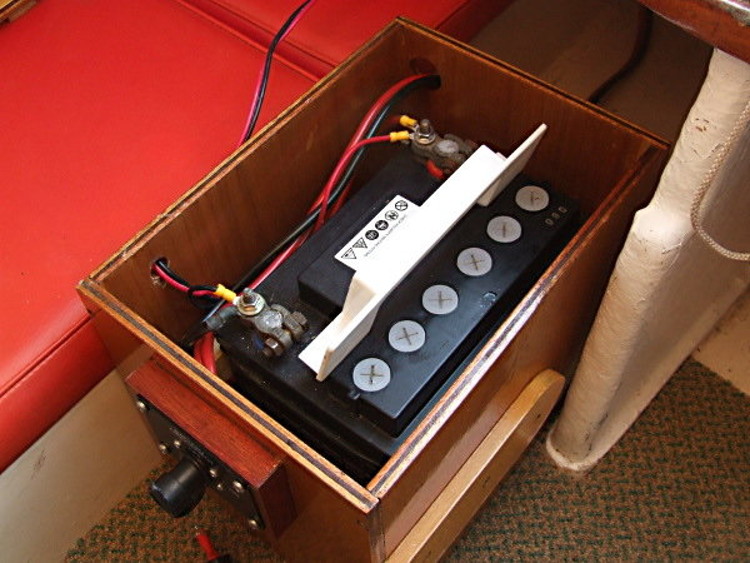

The conduit runs down the starboard side of the cabin, passing through a small hole in the bulkhead and on to the charge controller. Lengths of conduit continue to the battery box, located under the cabin threshold to starboard of the keel housing. There are deliberate gaps in the conduits at tight turns to facilitate re-threading should cable replacement ever be required.

The charge controller is mounted on a plywood panel so that cables can be neatly held out of the way and can pass easily into the conduit runs. The fuse fitted to the charge controller is that identified in the controller documentation. The cable that runs from the charge controller to the battery is multi-strand and was purchased to be the thickest gauge possible to push into the screw fittings and is considerably heavier gauge than that that is sealed into the solar panel. Again, this was passed on BSS inspection.

Running across the top of the quarter-berth and down to battery box, the cable from the charge controller is left unsupported for about 150mm as it leaves the conduit and passes into the battery box through a hole towards the forward end of the side of the box. Adequate support for cable runs is one of the criteria for the certificate. This arrangement was acceptable on inspection.

Cable ends must be terminated with a ring to fit over battery and switch terminals. The original terminals to these cables were not acceptable as fittings that bring the twisting tip of a screw in direct contact with the cable are not permitted. On screw fittings there needs to be mechanism to separate screw tip from the cable. Crimped or soldered are preferred and this type was fitted before the BSS inspection.

Another question on which the inspector must satisfy himself is:

"Do all electrical circuits pass through a battery isolator, or are those requiring a continuous supply otherwise protected?"

This required the fitting of a master switch that can now be seen on the front of the battery box. Additionally, it has been noted that should any devices be fitted to the power output of the charge control unit, they must all be fed through a single isolation switch, in order to satisfy the second part of this requirement. Suitable labelling of these two switches will become an issue should such equipment be fitted since the legend "Battery Disconnect", on the battery box isolator switch would be misleading.

The BSS demands that the battery is ventilated. It was judged that the holes to the side and rear of the battery box, where the cables exit, and the ventilation grill set high on the cabin door met this requirement.

The battery itself is held tightly to the side of the box by a length of wood held in place by nuts on long threaded rods. The box is then secured to the keel housing by lengths of wood and bolts with wing nuts.

The box was deliberately made over-sized to allow room to tuck surplus cable from both the charge controller and engine when the box is secured in its normal place. The surplus cable is needed to allow the box to be drawn forward into the cabin for battery inspection and topping up.

The lid is close fitting and drops into place, but has no catches or additional ventilation. Catches are unnecessary as when in its normal location, the lid cannot be lifted clear because the cockpit floor is low enough to prevent it being raised. All these other aspects of the battery installation were deemed acceptable.

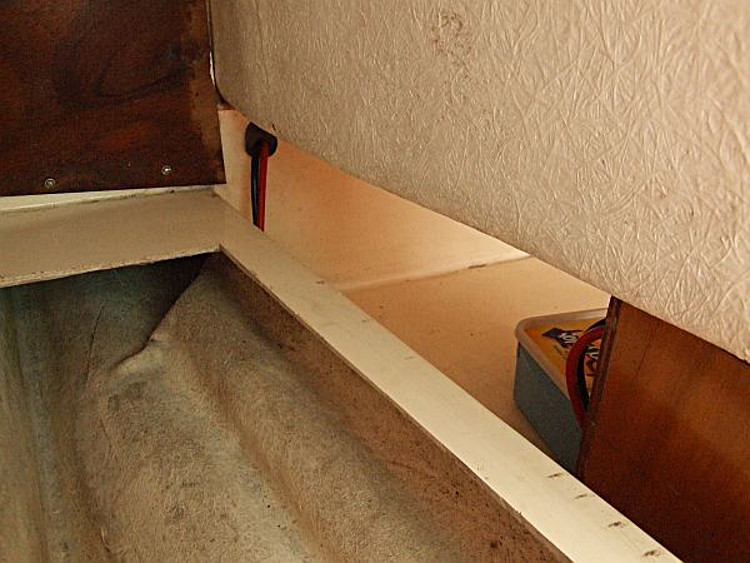

Above is shown the starboard quarter-berth, with its cushion removed, providing a better view of the rear corner of the battery box and showing the engine cable emerging from the box. This is the original Minn Kota cable supplied with the engine which terminates in the starboard cockpit locker.

The cable lies loose on the floor before it passes through a hole drilled in the bulkhead below the cockpit. Passage of the cable through the hole is protected from chaffing by a short length of pipe insulation. The cable is secured in any way to avoid any tight kinking that might otherwise occur when drawing the battery box forward for battery inspection and maintenance.

Once through the bulkhead the cable then passes along the hull floor until the far end of the cockpit locker where is rises in an unsupported loop to pass down into the locker cabinet. In the picture below it is possible to make out a stub of pipe insulation at the rear end of the cabinet indicating its entry point. The cable was installed here before the cockpit locker moulding was sealed in place. This is normally a dead area to which there is no access.

Finally, the cable emerges into the cockpit locker, again protected by pipe insulation where it passes through the locker walls. It terminates in the original Minn Kota plug. The cable from the engine is passed through a small notch in the bottom corner of the locker hatch. Keeping this connector inside the hatch at all times protects it from the elements.

Electrical Propulsion Systems

Electrical Propulsion Systems

No SeaHawk is known to have inboard electric propulsion and all the guidance in the BSS documentation appears to refer only to permanently fitted systems. In this case, while the boat is deemed to be electrically propelled on the inspector's check list, (presumably gaining a pass on the basis of the cable terminating in an acceptable plug) the "Propulsion motor & controller" and "Battery charging equipment" were checked as "Not applicable".

It seems that electric outboard engines are expected to be removed before the boat is tested under the scheme, or are treated as just another electrical appliance.

Outboards and Portable Fuel Systems

Outboards and Portable Fuel Systems

The full heading for this section of the regulations is "Outboard and Portable Combustion Engines and Portable Fuel Systems". No SeaHawk owner is known to carry a generator, a.k.a. a "portable combustion engine". However, even those with outboards with integral fuel tanks may regularly carry spare fuel, so have a "portable fuel system".

"Angela" has passed the BSS. She is used with an outboard motor that has an integral tank. Her owner is allowed to carry 2 x 5ltr fuel cans in one of the cockpit lockers. This has a door that has a foam seal along the top and sides but not the bottom edge. It also has a vent fitted which is 7.75in x 4in overall.

The cooker aboard Angela is the portable picnic type with a small gas canister. This is used in the usual cooker position in the cabin. When not in use the canister is to be removed and stowed with spare canisters in same cockpit locker as the outboard engine fuel.

Please use the Forum to report any variations in the implementation of or guidance given about the storage of fuel on board, when using an outboard engine.

Fire Extinguishing and Escape

Fire Extinguishing and Escape

Under the BSS the requirement is for vessels of up to 23ft to have two extinguishers on board with a minimum combined rating of 10A/68B. Only one is required if either there is either no cooking or no internal combustion engine on board. If a boat has permanent cooking facilities then a fire blanket is needed as well.

(It's all very well getting an exemption to reduce to one the number of fire extinguishers needed, but it does beg the question "Where is the fire risk?" when, as in Imagination's case, you have neither gas nor an internal combustion engine on board and demonstrates that those drafting the regulations never imagined that they would be applied to sailing craft, or is it just the cunning way that the drafter's got round the problem of knowing that most owners will take a stove on board?)

"Imagination" needed only one extinguisher, which had to be graded 5A/34B/C and kite marked. (Expect to pay around £15 for one of this type. Some BSS Inspectors will carry them as stock items for purchase at the time of the inspection.) A fire blanket was not be required for "Imagination" as the cooking facilities are not graded as "permanent" (interpreted by the BSS Office as not requiring an external piped gas supply), but is recommended when a portable stove is taken aboard.

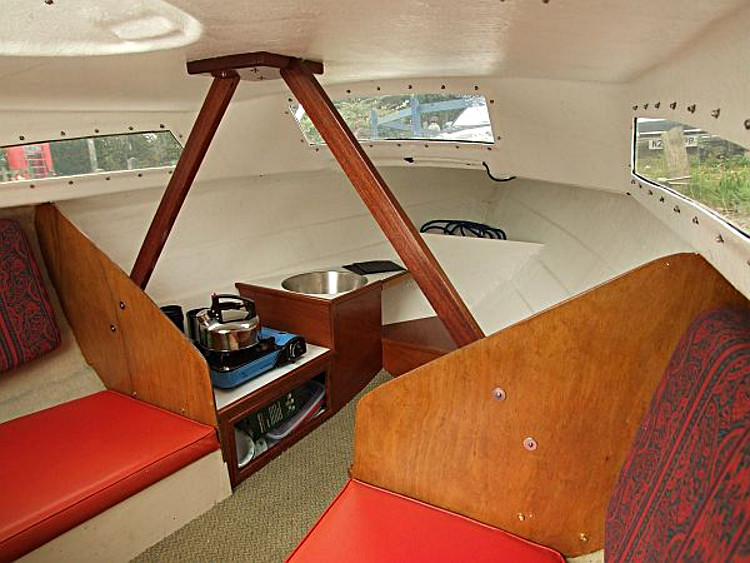

The BSS standard recommends that there should be two escape routes from each "accommodation space". While some owners of SeaHawks maximise the storage capacity constructing large bow lockers, on Imagination the forward locker was deliberately kept at low level. This both provides a level platform on which to stand when working on the head sail from within the cabin and the easiest possible access to the hatch for emergency escape.

Liquefied Petroleum Gas (LPG) Systems

Liquefied Petroleum Gas (LPG) Systems

No current SeaHawk owner has reported owning a fully installed LPG system with fuel stored remotely and piped to an appliance. (Please report any experience of BSS certification with such systems via the Forum.) If a cooker is used it is usually a self-contained portable type.

Note that navigation authorities normally have, within their bye-laws, a requirement to maintain craft to BSS certification standards. Accordingly it is not lawful to avoid any issues related to the BSS LPG regulations, simply by removing the cooker for the inspection.

A Camping Gaz "Bistro" stove is taken aboard "Imagination" when it is expected that hot drinks or simple meals are to be prepared. This model is fuelled with a standard "aerosol style" cartridge and has no fuel cut-off device on flame failure.

When on board the cooker is not bolted down. Instead, it simply sits on top of two long bolts (see photograph above). These bolts act as locating pins and are inserted into small holes in the chassis of the cooker. This appears to be a fully adequate method of ensuring the cooker does not move. The metal of the cooker chassis catches in the thread of the bolts, making it quite difficult even to lift the cooker off the two bolts. (The design of the chassis of this type of cooker varies enormously. The technique used on Imagination may not be appropriate to all, apparently similar, cookers.)

Such devices are not referred to in the BSS documentation but in January 2009 enquiries to the BSS office got the response that as the cooker is 'portable' (i.e. not 'installed', that is not connected to an external gas supply) it is assumed that the owner is present whenever the cooker is in use - therefore there is little danger of the flame blowing out and gas continuing to flow 'un-noticed'. Accordingly, the requirement for a flame failure device is waived.

The provisions on gas canisters, however, are applied. Canisters need to be stored in a position where any leakage will be directed safely overboard. It appears that some inspectors assess it as acceptable to store Gaz cartridges in the standard cockpit lockers. This is on the basis that these are totally sealed from the cabin and have side openings whose lowest point is lower than the cabin threshold, so the heavier-than-air LPG that escapes will drain into the cockpit and from there, down and through the transom bung holes. However, one SeaHawk owner is reported to keep his gas cartridges strapped down in the open near the fore peak where any leakage flows safely overboard. Whether this approach was adopted because the cockpit locker approach was deemed unacceptable by a BSS inspector is not known.

In April 2009 The BSS Office issued a Safety Alert concerning this type of stove, following incidents ashore. With some of these stoves it appears that it is possible for them to be used with the pan support or spill tray the wrong way up. With the pan support upside down and the burner on, heat is transferred onto the aerosol type gas canister in the body of the stove and after a time, the canister can burst causing a violent explosion and fireball. The BSS General Manager said, "We are urging boaters not to use these portable cookers in the poorly ventilated, tight confines of a boat", continuing, "Where a simple cooker is needed aboard, think about installing a marine spirit stove as an alternative to a portable gas cooker."

Appliances and Flues

Appliances and Flues

The bulk of this section addresses the central heating systems, catalytic heaters, refrigerators, and similar devices. No SeaHawk owners have reported carrying these on board. However, some questions will apply to boats that have a cooker present when inspected. These include: "Are all curtains, blinds and other textile materials near to appliances free of heat damage?" and "Is fixed ventilation in accordance with the relevant standard?"

The basic formula used for calculating the size of ventilation needed is:

Minimum effective area (mm2) = [2200xU]+[650xP]+[440xF]

U = total input rating (kW) for all appliances (including cookers)

without flues

P = number of people for which the compartment is designed

F = input rating (kW) for all open or closed flue appliances

The rules say, "The ventilation requirement needs to be split as equally as practicable between high level (ideally cabin roof), and low level." On SeaHawks neither the fore hatch nor the main cabin door are normally sealed. Both fit only very loosely over the upstands round the edge of the openings. BSS inspectors are including these unsealed gaps in the fore hatch and cabin hood as part of the ventilation allowance.

For a two berth boat with a single burner cooker rated at 1.5kW, this would require a vent of 1300mm sq for the two persons plus 3100mm sq for the cooker, a total vent of 4400mm sq.

When "Imagination" was due to be examined and some of the photographs, seen here, were supplied to the examiner, it was said:

"I think the gaps and grill will meet this - yes the vent is supposed to be split between high & low level, however, in this case I think so long as we have approx 1500mm sq around the gaps of the lower half of the cabin door (this should only need a 1 mm gap I reckon) we would comply."

Note that this makes no allowance for the fore hatch, which also has considerable gaps, as can be seen from the photograph illustrating the routing of the cable from the solar panel around the front of the cabin.

On examination, "Imagination" passed the ventilation requirements with no comment being made.

Pollution Prevention Systems

Pollution Prevention Systems

This section is concerned to ensure that any leakage of oil from engine equipment must be contained and prevented from being avoidably discharged overboard and that bilge pumping and toilet systems must be designed, installed and maintained in a way that minimises the risk of avoidable pollution.

Only those with inboard engines and sea toilets are likely to have issues with this section. Sea toilets must be sealed or have a valve to prevent discharge of raw sewage overboard as this is not allowed in BSS controlled waters. (Having a Porta Potti style toilet seems to mean an automatic pass.)

Please use the Forum if you have had to take any special measures to comply with the requirements of this section.